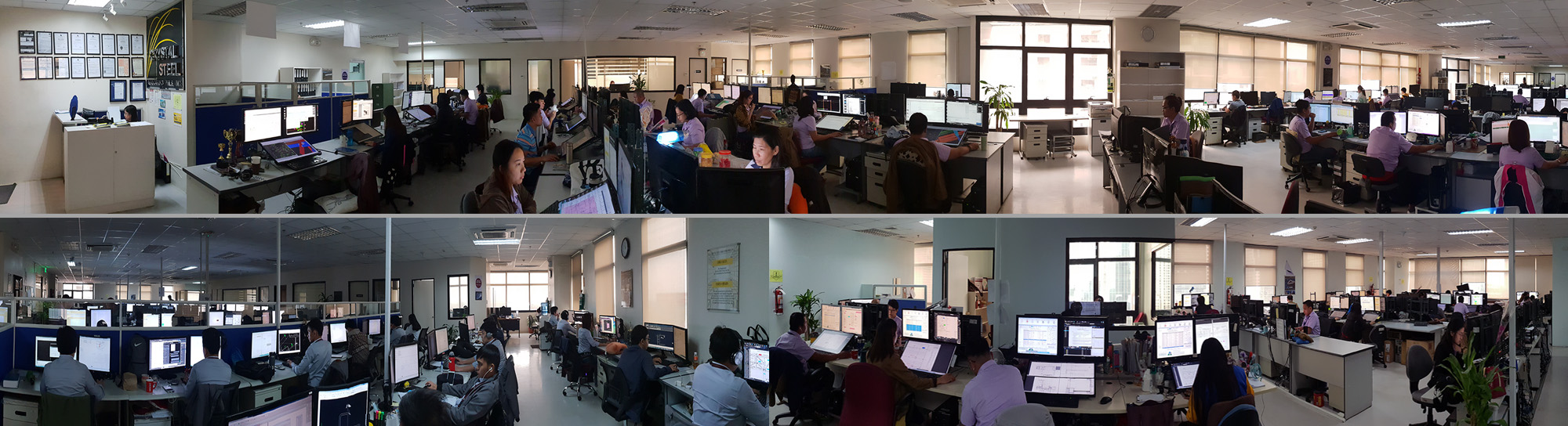

One of the largest steel detailing firms in the industry...in-house

No fabricator can assure you an on-time, quality job without controlling the engineering and shop drawing process. To accomplish this, Crystal Steel has created one of the largest steel detailing firms in the industry with 125 detailers, engineers, estimators and support staff in our 12,000 square foot Engineering Center, your project will be in good hands. We use state-of-the-art Tekla 3-D steel modelling software with BIM capabilities. Our Revit Structural, Revit Architectural, and Naviswork licenses allow us to work with architects, engineers, and other subcontractors from the design conception through completion of a project. We're ISO9001:2015 certified and members of the National Institute for Steel Detailing. Our engineering group can produce shop drawings quickly and accurately whether your job is 10 tons or 10,000 tons by bringing together the best people, processes and technology to cycle through drawing approvals and respond to field conditions faster with carefully crafted solutions. Using the latest communication technologies we can make our Philippine office feel like it is right next door.

People

- All of our detailers have degrees as engineers or architects

- Our drawing room supervisors have a combined 120 years of experience in construction management, engineering and steel detailing

- We have a licensed professional engineer on site as well as consulting engineers for more extensive design reviews and calculations

- We can contribute significantly to the constructability of design/build and fastrack projects

Process

- As a requirement of being an AISC Certified fabricator, we have extensive drawing control logging and tracking of all contract, shop and field drawings throughout the project lifecycle

- NISD, AISC & AWS procedures are followed in our detailing to insure conformance with the codes and standards that guide our industry

- Checking details begins at the model level and progresses all the way through the detailing process

Technology

- We have IntelliCAD, Tekla BIMSight, DESCON, and AutoCAD-LT seats on site, as well as trained operators for each

- 3D detailing is integrated with our shop fabrication systems via CNC

- We can import many engineering formats, helping to accelerate turnaround time from design change to received steel on the job

- We can export multiple formats to assist third parties with design, coordination or fabrication

- A 3D graphical model which allows you to view the structure from all angles, measure spacing and "walk" through the steel structure, is provided to clients on request. This tool has been used to coordinate mechanicals, help onsite superintendents envision/manage the job, discuss design suggestions with engineers of record and help owners understand progress (or roadblocks)

What does all this mean to you? Speed to the field.

- Crystal Steel can literally produce shop drawings overnight

- Control over our own engineering and detailing allows us to meet the most demanding schedules. In some cases, we have been able to deliver steel to the jobsite within one week of award and commencement of detailing

- Given the technological integration with our fabrication shops and the variety of automated equipment onsite, Crystal Steel can deliver properly fabricated steel to your jobsite quickly and keep your critical path moving forward

Quality Policy

CRYSTAL STEEL FABRICATORS PHILS., INC. recognizes that the disciplines of quality, health and safety, and environmental management are an integral part of its management function. The company views these as a primary responsibility and the key to good business, and can be realized by adopting an appropriate quality management system.

The organization’s quality standard calls for continuous improvement in all its activities and processes, thus, business will be conducted according to the following principles:

We will:

- Comply with all applicable laws and regulations

- Continuously improve our services and processes through efficient use of our best resources

- Communicate our quality objectives and performance against these objectives across the organization and to interested parties

- Maintain good business partnership with our clients and suppliers to achieve highest quality standards

- Ensure safe working environment, activities and processes for all employees and business associates

- Train our employees in the needs and responsibilities of quality management

- Adopt a forward-looking view on future business decisions which may have an impact on quality

It is also our aim that, with the total involvement and understanding of all our employees through the implementation of a documented quality management and information system, meeting the ISO 9001:2015 Standard, we will exceed the expectations of our customers and stakeholders.